Description

New features

Compared to F64’s previous model, the V3 features new encoder, joystick, rotary knobs, new thumb encoders and new motorsport clutches. New joystick and encoder knobs improve the ergonomics and the feedback of the buttons. New thumb encoders with radial bearings allow to change setting while driving without taking the hand of the wheel

New motorsport clutch Gen 4

Waterproof, shock resistant, wide temperature range

Smooth operation due to pre-tensioned ball bearing design

Contactless, on-axis hall sensor for linear, highly precise position measurement

Designed for harsh real racing environment

Precise and repeatable driver input

Compact and light weight design using aerospace aluminum

Zero play and smooth operation due to pre-tensioned ball bearings

Off-center actuation and asymmetric paddles possible

64 Inputs

14 x push buttons with positive tactile feeling

2 x protective button guards

2 x multifunctional 7-way joysticks (4 directions / rotate clock- anticlockwise/ push button)

2 x encoders inc. push button functionality, aluminum knob

2 x 12-position rotary switches, aluminum knob

2 x thumb encoders

2 x paddle shifters

2 x motorsport clutch paddles with electronic bite-point calibration

Magnetic paddle shifters

CNC machined and anodized out of automotive aluminum

Strong snap-action force

Alternative magnets to reduce force included

Reliable automotive switch

Contactless Clutch Paddles

Contactless, on-axis hall sensor for linear & unlimited operation

Precise and repeatable driver input

Waterproof, shock resistant, wide temperature range

Smooth operation due to pre-tensioned ball bearing design

Designed for harsh real racing environment

Precision CNC machined aluminum design

Market leading compact design

Contactless Clutch Paddle Electronic bite-point calibration

Precise adjustments in 1.0 % and 0.1 % increments

Change bite-point via configuration tool or directly on the wheel rim:

1. Push both joystick buttons for 1s to access bite-point mode

2. LED lights up to indicate calibration mode

3. Rotate left joystick for 1.0 % increments / right joystick for 0.1 % increments (LED flashes to indicate changes)

4. Exit calibration mode by pushing both joysticks again for 1s

Recommended procedure for finding best setting:

1. Enter calibration mode and set bite-point to high value, e.g. 80 %

2. Pull slave clutch only

3. Apply throttle

4. Reduce bite-point in 1.0 % increments (left joystick) until vehicle starts moving

5. Make test starts to fine tune desired bite-point setting

6. Exit bite-point calibration mode

Procedure for quick race starts

1. Pull both master and slave clutches

2. Apply throttle

3. Race start -> let master clutch snap

4. It will take less than 20 ms to reach desired bite-point

5. Slowly release slave clutch

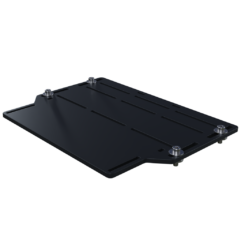

High Quality Finish

Maximum grip level from closed, ergonomic rubber grips

Machined out of automotive aluminum

Black anodized and laser engraved

Brushed front plate surface finish

Glass bed blasted paddle surface finish

Contactless Clutch Paddle Electronic bite-point calibration

Button Labels

50 pcs button labels each black and white

72 pcs encoder labels (blue, green, red, black, yellow, white)

Labels for various common steering wheel inputs

General Information

285 mm wheel diameter

6 x 70 mm bolt pattern

Robust, shielded coiled cable with industrial Binder M16 connector

Coiled cable connector length approx. 64 mm

Spacer may be required to create sufficient clearance to the wheel base

M5 x 12 mm stainless screws to mount QR included

Quick Release not included

To mount M5 threaded QRs, use captive screws

Mass: 1140 g

Compatible Wheelbases

SIMUCUBE 2

SIMUCUBE 1 (OSW, Mige)

Accuforce*

Leo Bodnar**

OSW (Argon)**

Simagic*

VRS Direct Force Pro***

Fanatec Podium Hub*

* Captive screws are required

** Wheelbase comes without QR

*** Longer screws are required

Reviews

There are no reviews yet.